Interfacing with LabVIEW

Here are some building blocks to interface an mbed with LabVIEW, allowing LabVIEW programs to interact with the real world. This could be used for things like:

- data acquisition in LabVIEW via sensors connected to mbed

- controlling actuators connected to mbed from LabVIEW

- LabVIEW programs with hardware-in-the-loop, where sensors and actuators are interfaced with mbed but calculations and control are in LabVIEW

We've created two ways for you to interface between LabVIEW and mbed.

- LabVIEW RPC This allows you to directly control the mbed using the RPC. For many applications it wouldn't be necessary to write any custom code for the mbed.

- Serial Communication These examples show how data can be transfered between the program running on mbed and your LabVIEW application.

LabVIEW Setup¶

To use mbed with LabVIEW, you need to have the NI-VISA drivers installed to give access to the USB serial port.

- http://www.ni.com/trylabview/ - LabVIEW trial version

- http://www.ni.com/visa/ - NI-VISA drivers for the serial port

With LabVIEW and NI-VISA installed, you should be ready to go.

LabVIEW RPC¶

We've created a set of vi's that expose a lot of the mbed interface using RPC. The vi's we've created allow you to create and control new objects or control objects that are created in the mbed code.

The LabVIEW vi's¶

Here are the vi's that allow you to interface with the RPC and some examples of their use.

- LabVIEW vi's: mbed_LVLibrary.zip - NB: For consistency the name of mbedSerial has been changed to SerialRPC

- Examples: mbed_LabVIEW_demos.zip

- LabVIEW Libraries for versions 8.5 and 8.6: LabVIEW_Previous_Version.zip

Relinking Files

When you download the files (especially the demos) they may not be in the same locations relative to the files they depend on as they were on the computer they were developed on. LabVIEW is very good at relinking files so just okay error messages or reconnect the files according to the locations in which you have saved them.

Using the LabVIEW RPC vi's¶

The LabVIEW vi's have been created to mirror the mbed api as closely as possible. They therefore take a similar object oriented approach. We create an mbed object and then using this create objects for each of the inputs and outputs. The vi's are contained in two folders:

- The "mbed Interface" folder includes all the vi's for creating and controlling inputs and outputs on mbed.

- The "Transport Mechanisms" folder contains the vi's for creating a connection to an mbed and then closing it.

We've provided the vi's as a zipped file which you can extract to any where on your computer. To make it a bit easier to access them we've also created a Library which might be a bit easier to develop with as you can drag vi's in from it. Just open the file mbed_LVlibrary from within LabVIEW.

Using the API¶

Information

To use these vi's your mbed needs to be running code which can receive and execute RPC commands. Information and examples of this, can be found on the Interfacing-Using-RPC page. Compile and run the program for RPC over serial to use the vi's on this page.

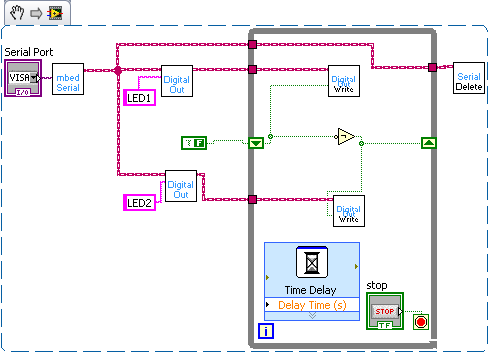

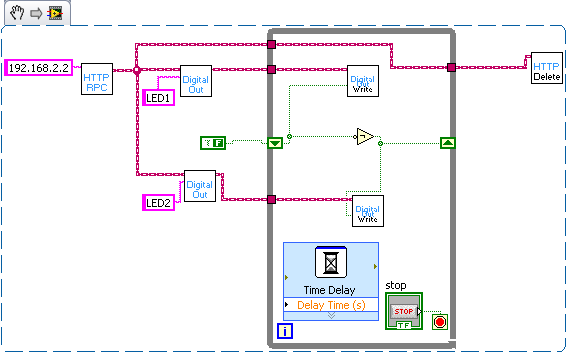

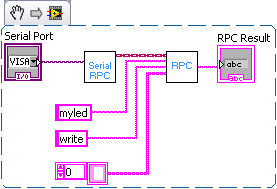

- First create an mbed interface by using a transport mechanism. This can be either SerialRPC or HTTPRPC.

- You can now create objects on mbed such as DigitalOut or AnalogIn. Wire up the input of a DigitalOut to the output from mbedSerial

- To create an object connect controls or constants to the pin number. Pins are passed as a string eg "p21" or "LED1"

- If you have an object created on mbed then you can tie to it by passings its name as a string into the existing object name.

- You can now execute the methods that are defined in the mbed api. For example you can execute a write block on a DigitalOut to set the value of the pin. Wire the write block to the object you want to act on and then add a control to set the value of the pin.

- Finally wire up the SerialRPC_delete method to the mbed wire so that the serial port is closed and is avaliable to other programs.

This is demonstrated in the LED flash example the block diagrams for which are displayed above. Note that only the write method is contained within the while loop as the object only needs to be created once at the start.

Using this approach you can connect multiple mbeds on different ports and control them from LabVIEW. The vi's have been designed to align as closely as possible with the api so looking in the Handbook should help explain what each method does. As its using the RPC the vi is directly calling the methods in the api.

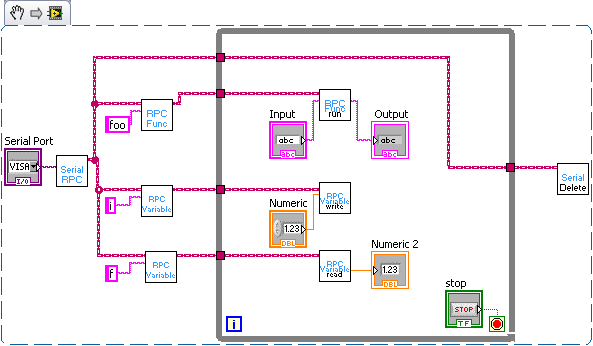

Using RPC with Custom Code¶

The RPC-Interface-Library provides a mechanism for quickly adding RPC functionality to your own code. This LabVIEW library includes support for the RPCFunction and RPCVariable Objects.

You can tie an RPCFunction or RPCVariable object to the corresponding object on mbed. You can then run the function or read and write to the variables which are attached.

The RPCVariable read and write blocks have both numeric and string inputs and outputs. You should wire to the appropriate one according to the type of variable it is corresponds with on mbed. The motor control IMU display demo at the bottom of the page show examples of these VIs in use.

Information

If you need to write your own entirely custom RPC command then you can use the RPC method that is part of the mbed class. Don't use the RPC methods in the Serial or HTTP class as this will prevent you from swapping transport mechanisms in the future. You can use this RPC method to create new interface classes. The name and method are passed as strings and the arguments are passed as an array of strings.

Serial Communication¶

Here are the mbed vi's we've created to communicate between mbed and LabVIEW:

- mbed-ni.zip - mbed read and write VI's, plus Hello World examples

Download these and use them as components in your LabVIEW designs.

The Protocol¶

To keep things simple, we're assuming the communication between LabVIEW and mbed is a line-based text protocol. That means every "packet" between LabVIEW and mbed is a string followed by a newline character (\n). The mbed-read.vi returns a line read from mbed every time you run it, and the mbed-write.vi writes a string to the mbed every time you run it, so you can use this however you want.

Whilst the line string is the underlying data, there are also some common cases we've added support for such as sending single numbers, or comma separated value (csv) "packets". The inputs and outputs supported are:

- A string (e.g. "hello" is transferred as "hello\n")

- A number (e.g. 1 is transfered as "1.0000\n")

- An array of strings (e.g. ["foo", "bar"] is transferred as "foo,bar\n")

- An array of numbers (e.g. [1, 0.5] is transferred as "1.000,0.5000\n")

These make it easy to work in LabVIEW without having to do lots of packing/unpacking/conversion yourself.

mbed Read Hello World¶

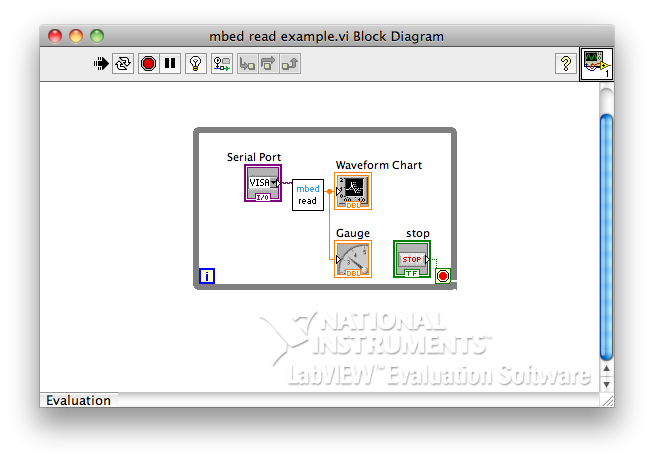

A simple labview example is included that plots the state of an AnalogIn input, which looks like:

And here is an example program to send some data:

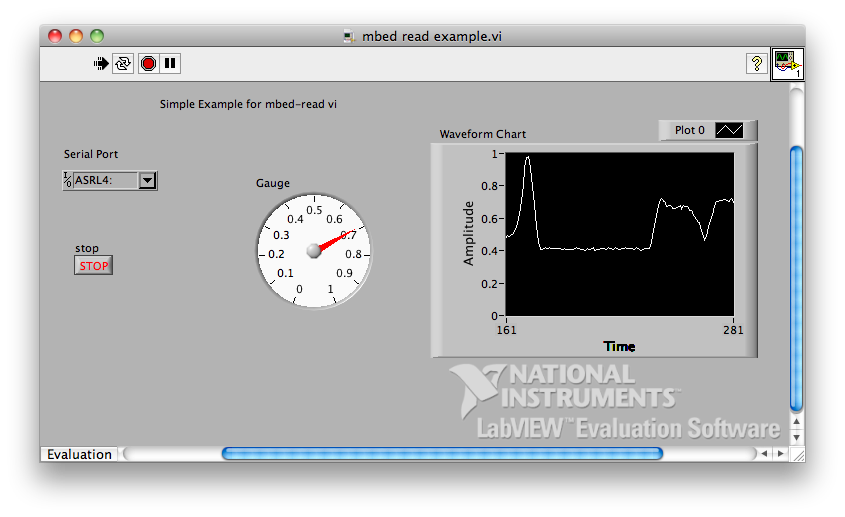

The resulting output once the mbed COM port number has been selected in the VISA control, and when modifying AnalogIn, looks like:

mbed Write Hello World¶

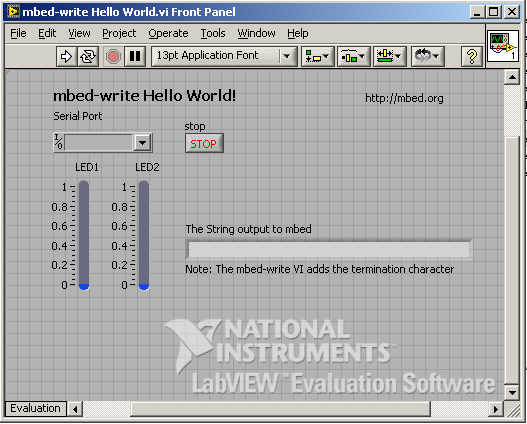

A simple labview example is included that controls the brightness of LED1 and LED2, which looks like:

And here is an example program that responds to the commands:

The control panel looks like:

Closed-Loop Motor Control Example - Serial Version¶

Here is an example of closed loop PID control of a motors position using LabVIEW. LabVIEW is very useful for experimenting with control because it allows you change the control constants on the go and you can graph the outputs of both demanded and actual response to see how well the control system is performing. Its also possible to pass any signal into your system as the demanded value, in this case a slider is used but this can be replaced with a function generator.

The basic serial version is for the serial examples is here:

Import program

00001 #include "mbed.h" 00002 #include "QEI.h" 00003 #include "Motor.h" 00004 00005 Serial pc(USBTX, USBRX); 00006 QEI Encoder(p29 ,p30, NC, 48); 00007 Motor Wheel(p23, p21, p22); 00008 00009 int main() { 00010 float MotorOutput = 0; 00011 Encoder.reset(); 00012 while (1) { 00013 pc.scanf("%f", &MotorOutput); 00014 float NoPulses = Encoder.getPulses(); 00015 00016 float Percentage = (NoPulses / 48) * 100; 00017 pc.printf("%f\n", Percentage); 00018 00019 Wheel.speed((MotorOutput - 50) * 2 / 100); 00020 00021 wait(0.005); 00022 } 00023 }

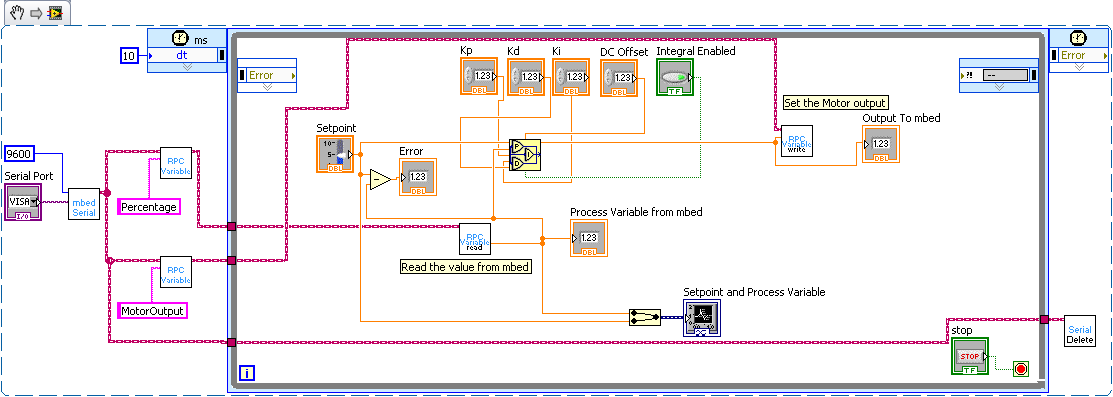

Closed-Loop Motor Control Example - RPC Version¶

Also, RPCVariable objects can be used to pass the position of the wheel as a percentage of one rotation and the output to the motor. The Motor that has been used is from Pololu and includes an encoder. The wheel position is found using the QEI library and the motor is controlled using an L293D and the Motor library.

Here is the front panel and the block diagram for the LabVIEW vi. (Pictures of the setup coming soon!)

The red line shows the demanded value and the white line the actual motor position. As the motor has a gear box its quite slow and theres a lot of damping this means that the control is very simple and changing Kp just changes how long it takes to get to the demanded value. However at some values the porportional output to the motor becomes too low to actually drive the motor before it reaches the demanded position, in which case the integral control can be used elimiate the error.

Here is the code that was running on mbed for this demo.

Import program

00001 /** 00002 * Copyright (c)2010 ARM Ltd. 00003 * Released under the MIT License: http://mbed.org/license/mit 00004 */ 00005 00006 #include "mbed.h" 00007 #include "QEI.h" 00008 #include "Motor.h" 00009 #include "SerialRPCInterface.h" 00010 00011 //Create the interface on the USB Serial Port 00012 SerialRPCInterface SerialInterface(USBTX, USBRX); 00013 00014 QEI Encoder(p29 ,p30, NC, 48); 00015 Motor Wheel(p23, p21, p22); 00016 00017 //Create float variables 00018 float MotorOutput = 50; 00019 float Percentage = 0; 00020 00021 //Make these variables accessible over RPC by attaching them to an RPCVariable 00022 RPCVariable<float> RPCMotorOut(&MotorOutput, "MotorOutput"); 00023 RPCVariable<float> RPCPercentage(&Percentage, "Percentage"); 00024 00025 int main(){ 00026 00027 Encoder.reset(); 00028 float NoPulses; 00029 00030 while(1){ 00031 NoPulses = Encoder.getPulses(); 00032 Percentage = ((NoPulses / 48) * 100); 00033 //RPC will be used to set the value of MotorOutput. 00034 Wheel.speed((MotorOutput - 50) * 2 / 100); 00035 wait(0.005); 00036 } 00037 }

IMU Demo¶

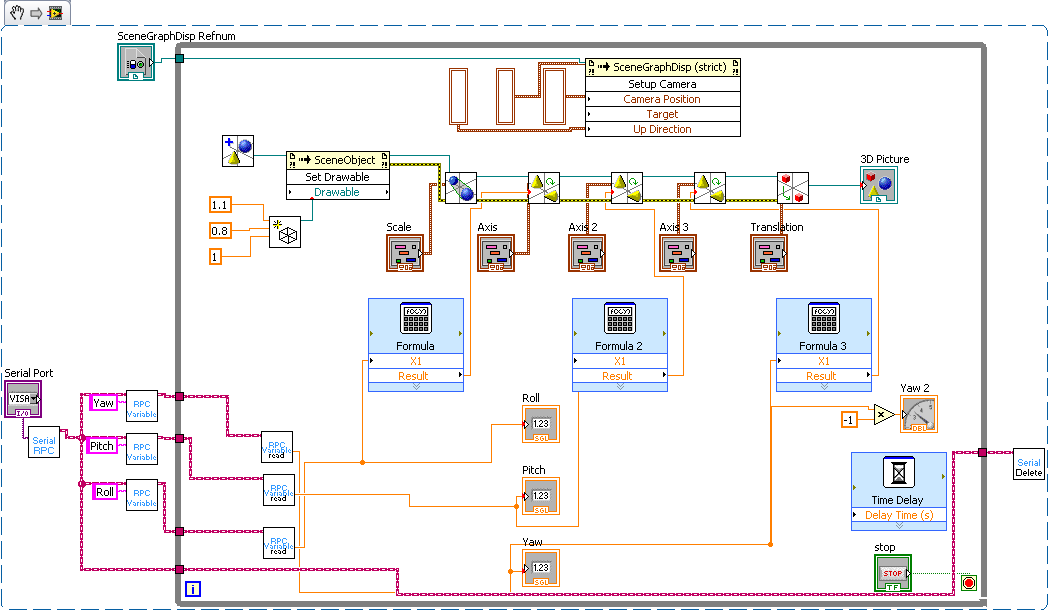

As well as control LabVIEW can also be used to visualise data in a much more intuitive way than just printing it to a terminal. This is the LabVIEW VI featured on Aaron's IMU page where its used to show the output from the IMU. Its gives a visual output which shows the measured orientation. Its then a lot easier to see what the values mean and how errors acumulate than when you're looking at a long list of figures at a terminal. The program running on mbed uses the example program on the IMU page but with a few changes. As the IMU class doesn't support RPC, RPCVariable objects were used to pass the yaw pitch and roll variables and so a few lines were altered in the example program:

//With the other object intialisations

float Roll, Pitch, Yaw;

//Now attach these varaibles to RPCVariable Objects

RPCVariable<float> rpcRoll(&Roll, "Roll");

RPCVariable<float> rpcPitch(&Pitch, "Pitch");

RPCVariable<float> rpcYaw(&Yaw, "Yaw");

SerialRPCInterface LabVIEW(USBTX, USBRX);

//And the while loop in main becomes

while (1) {

wait(FILTER_RATE);

Roll = toDegrees(imuFilter.getRoll());

Pitch = toDegrees(imuFilter.getPitch());

Yaw = toDegrees(imuFilter.getYaw());

}

This is the Block diagram for the VI which visualises the output.